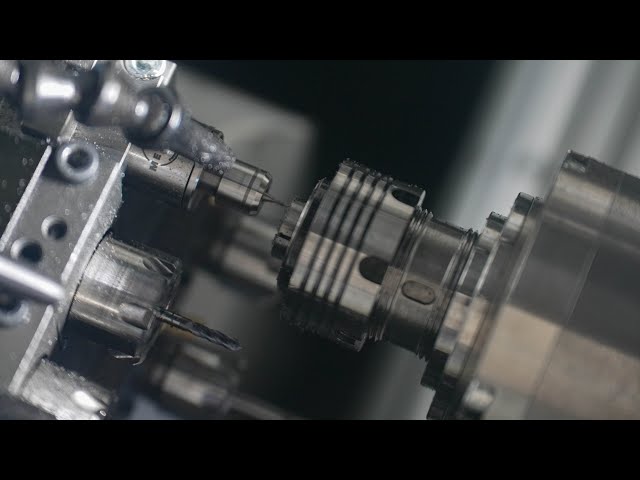

A Swiss lathe is a type of lathe that is designed for extremely precise work. The term “Swiss” refers to the country of origin for this type of lathe. Swiss lathes are known for their ability to produce very small parts with a high degree of accuracy.

Checkout this video:

Checkout this video:

History of the Swiss Lathe

The Swiss lathe is a type of lathe that was first developed in Switzerland in the early 1900s. Swiss lathes are unique because they are designed to cut very small parts with a high degree of accuracy. This makes them ideal for use in the manufacture of watch components, ball bearings, and other Precision Engineered parts.

Swiss lathes are also known as “sliding headstock lathes” because the headstock (the part of the lathe that holds the cutting tool) is mounted on a slide instead of being fixed in place. This allows the cutting tool to be moved very accurately along the X, Y, and Z axes, which increases the precision of the finished product.

Swiss lathes are usually computer-controlled (CNC), which means that they can be programmed to produce very complex shapes. They are also capable of producing parts with extremely tight tolerances (e.g. +/- 0.0001 inches).

Today, Swiss lathes are used by manufacturers all over the world to produce a wide variety of precision-machined components.

How the Swiss Lathe Works

A Swiss lathe is a type of computer numerical control (CNC) lathe that is used for high-precision machining. Invented in Switzerland in the 1950s, the Swiss lathe is also known as a sliding headstock lathe or a Citizens machine. The term Swiss lathe is used to describe both the machine tool and the machining process.

The main difference between a Swiss lathe and a conventional CNC lathe is the number of axes on which the cutting tool can move. A Swiss lathe has at least three axes (X, Y, and Z), but most have four or five (A and B are the most common additional axes). This allows for more complex shapes to be machined than with a conventional two-axis CNC lathe.

The other major difference between a Swiss lathe and a conventional CNC lathe is the way in which the workpiece is supported. On a Swiss lathe, the workpiece is supported on both ends (known as live tooling), whereas on a conventional CNC lathe, it is only supported on one end. This makes Swiss machining ideal for long, slender workpieces that might otherwise be difficult to support properly.

Benefits of Using a Swiss Lathe

A Swiss lathe is a type of computer numeric controlled (CNC) lathe that is designed specifically for high precision machining. Swiss lathes are often used for small to medium parts that require tight tolerances, such as those used in the medical, aerospace, and electronics industries.

There are several benefits of using a Swiss lathe for CNC machining, including:

-Ability to hold tight tolerances: Swiss lathes are designed for precision machining, which means they can hold extremely tight tolerances. This is especially important for parts that will be used in critical applications or that require a high level of finish.

-High speed and productivity: Swiss lathes are also designed for high speed and productivity, which means they can produce parts quickly and efficiently. This is especially important for high volume production runs.

-Flexibility: Swiss lathes are very versatile and can be used for a wide variety of machining applications. This means they can be used to produce a wide range of parts, from simple to complex.

-Ease of use: Swiss lathes are typically easy to operate and program, even for complex parts. This makes them an excellent choice for both experienced machinists and those new to CNC machining.

Types of Swiss Lathes

There are several different types of Swiss lathes, each designed for specific applications. The most common type is the live tooling lathe, which is used for general purpose machining. Live tooling lathes have the ability to use a variety of cutting tools, making them versatile machines.

Another type of Swiss lathe is the CNC Swiss lathe. These machines are computer controlled and can be programmed to perform a variety of tasks. CNC Swiss lathes are typically used for more complex machining projects.

The final type of Swiss lathe is the gang tool Swiss lathe. These machines are designed for high volume production and can be equipped with a variety of cutting tools. Gang tool Swiss lathes are typically used in manufacturing applications.

How to Choose the Right Swiss Lathe

Swiss lathes are some of the most precise and versatile machines used in machining today. That’s why choosing the right one for your shop is critical to your success. But with all the different models and manufacturers on the market, how can you be sure you’re making the best decision for your business?

Here are a few factors to keep in mind when shopping for a Swiss lathe:

* Spindle size and power – The size of the spindle will dictate the maximum diameter of the material that can be machined. More power is always better, but it’s especially important if you plan on machining tough materials or large diameter parts.

* Chuck size – Again, this will be dictated by the maximum diameter of the parts you want to machine. If you plan on making small parts, then a smaller chuck may suffice. But if you want the versatility to machine larger parts, then choose a lathe with a larger chuck.

* Number of axes – The more axes a lathe has, the more complex parts can be machined. If you only need to turn cylindrical parts, then a 2-axis lathe will suffice. But if you want to add capabilities like drilling or milling, then look for a 3- or 4-axis model.

* CNC or manual – CNC lathes offer much greater flexibility and precision than manual machines. If you only plan on turning simple parts, then a manual lathe may be all you need. But if you want to expand your capabilities or increase throughput, then CNC is the way to go.