A punch press is a machine used to create holes in materials using a die and punch. The machine works by using a die to cut through the material and a punch to create the hole.

Checkout this video:

Checkout this video:

What is a Punch Press?

A punch press is a type of machine press that uses a die and punch to create holes in sheet metal. The punch press is a versatile machine that can be used to create a variety of hole sizes and shapes. The punch press can also be used to create other features in sheet metal, such as slots, embossments, and louvers.

A punch press is a type of machine press that uses a die to shear, blank, draw, or form metal.

A punch press is a type of machine press that uses a die to shear, blank, draw, or form metal. The die is mounted on a ram that moves up and down in a vertical line. The ram can be actuated by a hand lever, foot pedal, air cylinder, or hydraulic cylinder. Punch presses are used in a variety of industries, including automotive, aerospace, electronics, and appliance manufacturing.

Punch presses can be classified by their mechanism of operation:

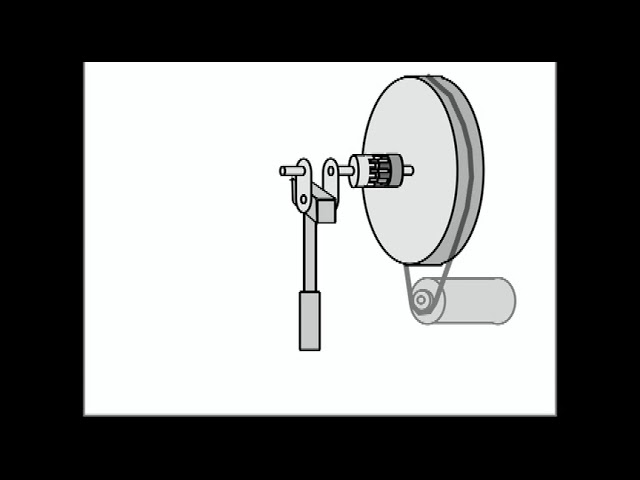

-Mechanical punch presses use a flywheel to store energy and transfer it to the ram. The flywheel is connected to the crankshaft by means of a clutch. As the flywheel rotates, it stores energy in its kinetic form. When the operator wants to activate the machine, they disengage the clutch and the flywheel transfers its energy to the crankshaft. This rotational energy is then transferred to the ram via gears and linkages, causing it to move up and down in a reciprocating motion.

-Hydraulic punch presses use hydraulic cylinders to provide the force needed to operate the machine. A hydraulic pump generates fluid pressure that is used to move the ram up and down.

-Pneumatic punch presses use compressed air to operate the machine. A pneumatic pump generates air pressure that is used to move the ram up and down.

Punch presses are typically used in the automotive and aerospace industries.

Punch presses are typically used in the automotive and aerospace industries. The press uses a die set to cut, shape, or form metal sheets. The process is completed by a punch, which is a metal rod with a sharp tip that strikes the workpiece to create the desired shape.

Punch presses are classified according to the size of their bed, which is the metal platform that holds the workpiece in place during punching. There are three main bed sizes: small (up to 12″), medium (12″ to 36″), and large (larger than 36″). Small punch presses are typically used for light work, such as making small parts for electronic devices. Medium and large punch presses are used for heavier work, such as making car parts.

Punch presses can be operated manually or automatically. Manual punch presses are operated by a hand lever that is connected to the punching mechanism. Automatic punch presses are operated by an computer-controlled system that automatically feeds the workpiece into the punching mechanism.

How Does a Punch Press Work?

A punch press is a type of machine that uses a die to cut or shape metal. The die is a template that has the desired shape cut into it. The die is attached to the punch press, and the workpiece is placed on a lower die.

A punch press consists of a bed, a ram, and a die.

A punch press is a type of machine press that uses a ram to apply strong, linear force to a workpiece, usually to cut holes or shape it in some way. Punches and dies are mounted on the bed or ram of the punch press, and the workpiece is positioned between them. When the ram moves down, it applies pressure to the workpiece, which is cut or shaped accordingly.

Punch presses can be manually operated, but most are now automated. CNC (computer numerical control) punch presses are controlled by a computer, which allows for greater precision and efficiency.

The bed is where the workpiece is placed.

A punch press is a type of machine press used to cut holes in material. It can be stand-alone or integrated into a complete working line. A punch press consists of a bed, where the workpiece is placed, and a ram, which contains the cutting tool. The ram moves up and down, and the cutting tool moves in and out, to cut the desired shape out of the workpiece.

Punch presses can be operated manually or automatically. Manual punch presses are operated by a handle that is connected to the ram. The operator pulls the handle to lower the ram and cutting tool onto the workpiece. Automatic punch presses are controlled by a computer program that determines the position of the cutting tool and regulates the speed and force of the ram.

Punch presses can be used to cut a variety of materials, including metal, plastic, wood, and composite materials. They are commonly used in sheet metal fabrication applications.

The ram is the part of the machine that moves up and down to strike the workpiece.

The ram is the part of the machine that moves up and down to strike the workpiece. A die is attached to the bottom of the ram and a punch is attached to the top. When the ram moves down, the punch strikes the workpiece, cutting out a shape.

The die is the part of the machine that contains the cutting or forming tools.

A punch press is a machine that uses hydraulic or pneumatic pressure to push a tool, called a die, through material to cut or form it. The material can be anything from sheet metal to rubber.

The die is the part of the machine that contains the cutting or forming tools. It is mounted on the ram, which is the part of the machine that provides the force to push the die through the material. The ram can be operated manually or automatically.

Punch presses are classified according to their frame types. There are four main types of punch press frames:

-Gap frame: A gap frame punch press has a large opening between the bed and ram. This design allows for easy alignment of dies and greater accessibility for loading and unloading material.

-Oblique frame: An oblique frame punch press has a slanted bed, which provides better access to the working area of the machine.

-Straight side frame: A straight side frame punch press has vertical columns on either side of the bed, which gives it more rigidity than a gap or oblique frame machine. This design is well suited for high production applications.

-Double column: A double column punch press has two beds, one on top of the other, connected by columns. These machines are very large and are used for high production applications where parts need to be made very quickly.

What are the Benefits of Using a Punch Press?

A punch press is a type of machine that uses a die to cut or shape metal. The punch press can be used to cut or shape a variety of materials, including paper, plastic, and metal. Punch presses are often used in the manufacturing of products such as cars, airplanes, and appliances. There are a few benefits of using a punch press.

Punch presses offer a number of benefits, including:

Punch presses offer a number of benefits, including:

-Increased productivity: A punch press can produce parts faster than a traditional machining process, such as CNC milling.

-Improved accuracy: Punch presses can produce parts with very tight tolerances.

-Reduced setup time: Punch presses require less setup time than traditional machining processes.

-Lower costs: Punch presses can often be used to produce parts at a lower cost than traditional machining processes.

Increased accuracy

When it comes to stamping out parts or products, a punch press is far more accurate than a human hand. In fact, it can be up to 10 times more accurate. This means that there are fewer defects in the finished product and less waste overall.

Increased productivity

Punch presses are one of the most commonly used machines in sheet metal fabrication shops. They are versatile and can be used for a variety of applications, including cutting, forming, and drawing. Punch presses can also be equipped with a variety of attachments to increase their versatility.

One of the biggest benefits of using a punch press is increased productivity. Punch presses are faster and more accurate than traditional methods such as hand cutting or forming. This increased accuracy means that fewer parts need to be scrapped, which saves time and money. In addition, punch presses can be automated, which further increases productivity.

Another benefit of using a punch press is that it gives the operator more control over the cut or formed part. This is because the operator can precisely control the speed and pressure of the punch press. This allows for parts to be produced with closer tolerances, which is often necessary for precision applications.

In addition to increased productivity and precision, punch presses also offer other advantages. For example, they are relatively easy to operate and maintain. They are also relatively safe to use, as long as proper safety procedures are followed.

Increased safety

When a large number of parts need to be produced quickly, a punch press is the best solution. Punch presses can rapidly produce large quantities of parts with a very high degree of accuracy. In addition, punch presses are much safer than other types of machines because they are fully enclosed. This means that there is no danger of fingers or clothing getting caught in the machinery.