This blog will show you how to program a CNC machine. You will need to know some basic information before you can start programming.

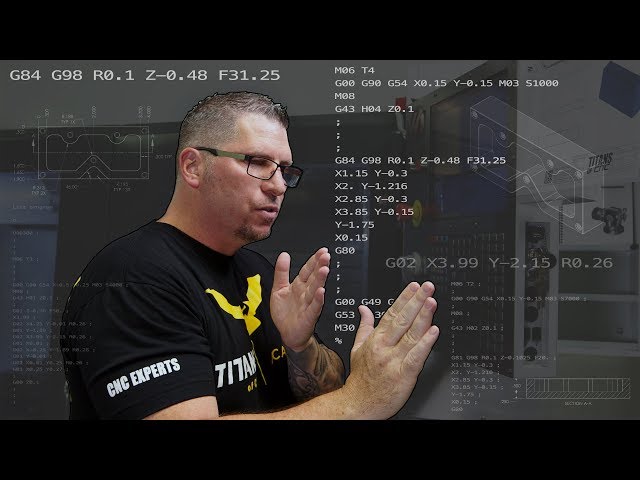

Checkout this video:

Checkout this video:

CNC Machine Basics

CNC machines are computer-controlled machines that are used to create complex products and parts. These machines can be programmed to create a wide variety of products. In order to program a CNC machine, you will need to have a strong understanding of the machine’s capabilities as well as the specific software that is used to program it.

What is a CNC machine?

CNC stands for Computer Numerical Control. A CNC machine is a machine that is controlled by a computer. The computer tells the machine what to do and how to do it.

CNC machines can be used to do a variety of things. They can be used to make parts for products, they can be used to make tools, and they can be used to make prototypes. CNC machines can even be used to make other CNC machines.

How does a CNC machine work?

CNC machines are computer controlled tools that can be used to create complex parts and designs. The “CNC” in CNC stands for “computer numerical control.” This means that the machine is controlled by a computer, which tells it what to do and how to do it. CNC machines are often used in manufacturing, but they can also be used in woodworking, metalworking, and even engraving.

CNC Machine Programming

CNC machine programming is a process that tells a CNC machine how to make a part. This process can be done manually by the operator, or it can be done through a computer. If you are programming a CNC machine manually, you will need to know G-code. If you are programming a CNC machine through a computer, you can use any number of CAD/CAM software programs.

What is CNC machine programming?

CNC machine programming is the process used to create a program that will control a CNC machine. The program is written in a particular language which tells the CNC machine what movements to make, how fast to move, and what tools to use.

To create a CNC program, the programmer must first understand the capabilities and limitations of the CNC machine they will be using. They must also be familiar with the workpiece material and the specific cutting tools that will be used. With this information, the programmer can then create a program that will produce the desired results.

CNC machine programming can be done manually or through the use of computer software. Manual programming is done by creating a program by hand, using graphic symbols and instructions to represent the toolpaths and cutting operations. This method is often used for simple programs or for programs that require only small changes.

Computer software can be used to create more complex programs, or to make changes to existing programs. There are many different types of software available, each with its own capabilities and features. Some software is designed specifically for CNC programming, while other software can be used for general purpose CAD/CAM applications.

How to program a CNC machine?

CNC machines are programmable logic controllers (PLC) that use a computer to read a machining program and turn it into motion. The machine toolpath is controlled by a series of coded instructions that tell the machine what motions to perform, how fast to move, and what points to cut. These instructions are called CNC codes or G-codes.

G-codes are a standardized set of numeric codes that correspond to specific machining operations. For example, the code G97 tells the machine to perform continuous cutting operations, while G00 tells the machine to perform rapid linear motion. By inputting the correct G-codes, you can create complex three-dimensional shapes and sizes with a CNC machine.

To program a CNC machine, you will need to create a file called a part program. This file contains the instructions for the CNC machine to follow when performing a machining operation. Part programs can be created using any text editor, but there are also specialized software programs that make creating part programs easier.

Once you have created your part program, it must be loaded onto the CNC machine before it can be executed. Most CNC machines have USB ports that can be used to transfer files from your computer to the machine. Once the file is transferred, the machine will execute the machining operation according to the instructions in the part program.

CNC Machine Maintenance

Before starting any maintenance on your CNC machine it is important to unplug the machine from any power source. Once the machine is unplugged, you will want to clean all the visible dirt and debris from the outside of the machine. It is also important to check for any loose bolts or screws.

What is CNC machine maintenance?

CNC machine maintenance is the care and servicing of CNC machines to prevent malfunction and extend their working life. Maintenance can be performed by the user/operator, although regular maintenance contract with the machine’s supplier is often recommended.

How to maintain a CNC machine?

CNC machines are often used in manufacturing and industrial applications, where they are responsible for fabricating parts and products. Like any other type of machinery, CNC machines require regular maintenance to ensure optimal performance.

There are several simple steps that can be taken to maintain a CNC machine. First, it is important to keep the machine clean. Dust and debris can build up on the moving parts of the machine, causing them to wear down over time. Second, it is important to keep the machine lubricated. This will help to prevent wear and tear on the moving parts, and will also help to keep the machine running smoothly.

Third, it is important to check the alignment of the machine regularly. Over time, vibrations can cause the machine to become misaligned, which can lead to inaccurate cuts or even damage to the machine. Finally, it is important to regularly check the software that controls the CNC machine. Updates and patches may be available that can improve the performance of the machine or fix software bugs.